- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Bronze Casting

- Aluminum Castings

- Leak Proof Casting

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Non Ferrous Castings

- Power Distribution Casting

- Impeller Bronze Casting

- Sand Casting

- Aluminium Sand Casting

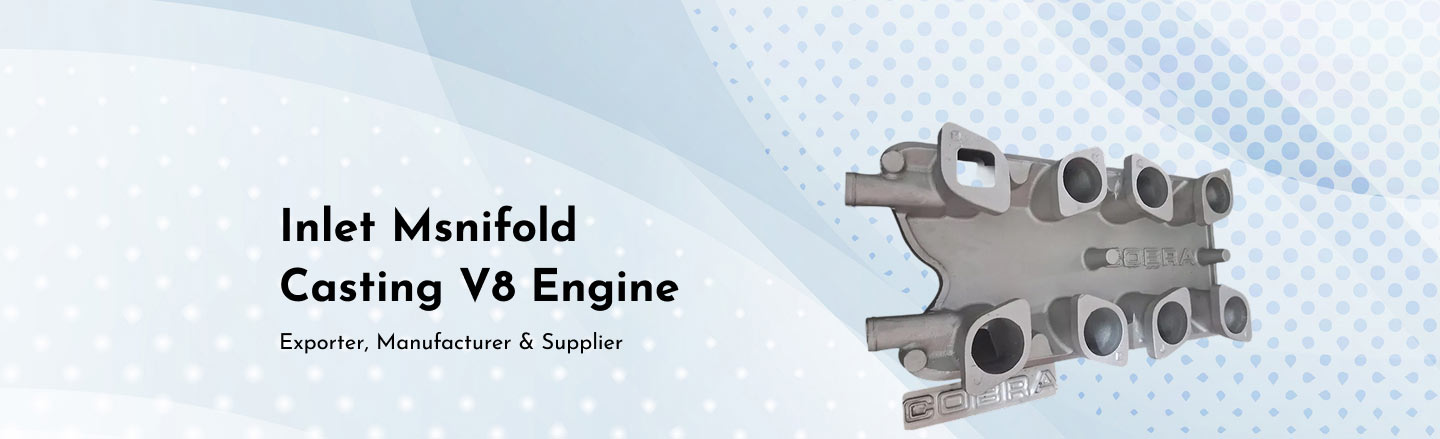

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

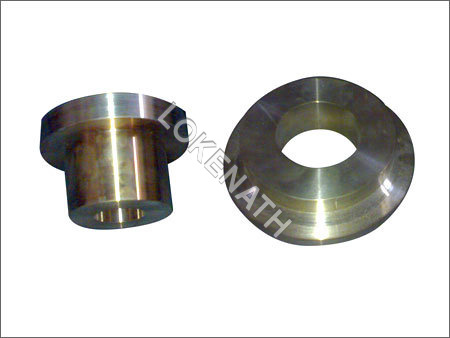

Aluminium send Castings

450 INR/Bale

Product Details:

- Product Type Industrial Casting

- Casting Process Manual

- Application Automobile, Machinery, Electrical

- Method Sand Casting

- Surface Treatment Sand Blasting

- Weight (kg) 2.5

- Color Silver Grey

- Click to view more

X

Aluminium send Castings Price And Quantity

- 1 Unit

- 450 INR/Bale

Aluminium send Castings Product Specifications

- Silver Grey

- Sand Casting

- Industrial Casting

- Automobile, Machinery, Electrical

- Sand Blasting

- Manual

- 2.5

Aluminium send Castings Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- Per Day

- Days

- Yes

- Asia

- All India

Product Description

We have carved a niche in this field by offering excellent quality Aluminium Castings to our clients in different specifications. These castings are manufactured at our premises using excellent quality aluminium with the aid of ultra-modern techniques by ingenious professionals. Especially used for providing desired shape to various components, the offered castings find application in automotive, electrical and many other industries. Moreover, our clients can avail the provided Aluminium Castings at reasonable prices from us.

Key points:

- Accurate dimensions

- Long life

- Premium finish

- Cherished for flawlessness

Aluminum sand casting is a widely used, versatile metal casting process where molten aluminum is poured into a sand mold to create a desired part. The process is known for its ability to produce intricate and complex geometries with high accuracy, making it suitable for a wide range of applications.

Here's a breakdown of the process:

1. Pattern Creation: A reusable pattern, resembling the final part, is created from materials like wood, metal, or plastic.

2. Mold Making: The pattern is embedded in a flask (a container) filled with sand (often reinforced with clay or resin). The sand is compacted around the pattern to create a mold cavity.

3. Gating System: Runners (channels) and risers (reservoirs) are incorporated into the mold to guide the molten aluminum into the cavity and manage shrinkage during cooling.

4. Melting and Pouring: The aluminum alloy is melted and then poured into the prepared mold cavity through the gating system.

2. Mold Making: The pattern is embedded in a flask (a container) filled with sand (often reinforced with clay or resin). The sand is compacted around the pattern to create a mold cavity.

3. Gating System: Runners (channels) and risers (reservoirs) are incorporated into the mold to guide the molten aluminum into the cavity and manage shrinkage during cooling.

4. Melting and Pouring: The aluminum alloy is melted and then poured into the prepared mold cavity through the gating system.

5. Cooling and Solidification: The molten aluminum cools and solidifies within the mold, taking the shape of the cavity.

6. Knockout and Cleaning: The sand mold is broken away (knocked out), and the casting is removed. The casting is then cleaned, and any excess material from the gating system is removed.

7. Finishing: The casting may undergo further finishing processes like machining, polishing, or surface treatments to meet specific requirements.

6. Knockout and Cleaning: The sand mold is broken away (knocked out), and the casting is removed. The casting is then cleaned, and any excess material from the gating system is removed.

7. Finishing: The casting may undergo further finishing processes like machining, polishing, or surface treatments to meet specific requirements.

Key features of aluminum sand casting:

-

Can produce parts with complex shapes and varying sizes.

-

Relatively low cost, especially for smaller production volumes and large parts.

-

Used in automotive, aerospace, electronics, construction, and various industrial equipment.

-

Utilizes various aluminum alloys, each with specific properties (strength, heat resistance, etc.).

-

Modern sand casting processes often incorporate sand reclamation and recycling to minimize environmental impact, according to a manufacturing resource.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email