- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

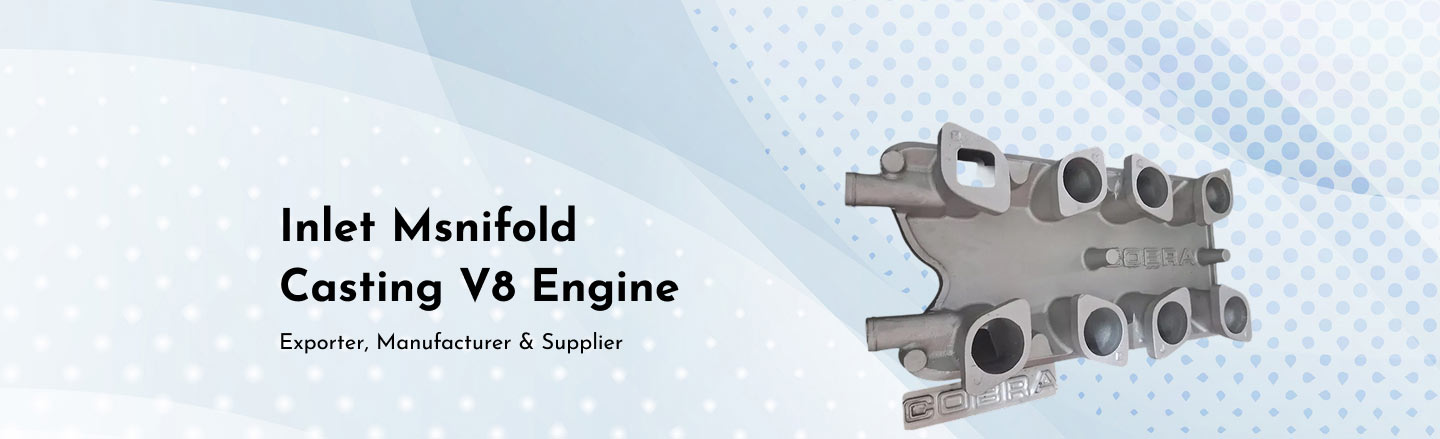

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

Cab Roof Auminium Moulds

350 INR/Bale

Product Details:

- Product Type Aluminium Moulds

- Casting Process Gravity Casting

- Application Automotive Cab Roof Moulding

- Method Die Casting

- Surface Treatment Anodized

- Color Silver

- Click to view more

X

Cab Roof Auminium Moulds Price And Quantity

- 1 Unit

- 350 INR/Bale

Cab Roof Auminium Moulds Product Specifications

- Die Casting

- Silver

- Aluminium Moulds

- Anodized

- Automotive Cab Roof Moulding

- Gravity Casting

Cab Roof Auminium Moulds Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- Per Day

- Days

- Yes

- Asia

- All India

Product Description

With great zeal and enthusiasm, we are successfully engaged in providing our clients with an excellent quality range of Cab Roof Auminium Moulds. Using top grade aluminium, these molds are manufactured by a troop of dexterous professionals. Best to be used in metal fabrication industry, the offered molds are used to produce seamless molds. In addition, the offered Cab Roof Auminium Moulds can be bought by our valued patrons at rock bottom rates.

Features:

- Long lasting

- Excellent strength

- Perfect to use

- Light weight

Cab roof aluminum molds are used in the automotive industry to shape and form the outer roof panel of a vehicle's cab, often for energy-saving and accident-resistant designs. These molds, typically made from cast aluminum or CNC machined aluminum, are crucial for achieving the desired shape, aesthetics, and aerodynamic properties of the vehicle's roof. They can be used for both prototype and mass production of cab roofs, and may also be used for other parts like tractor canopies and other plastic components.

Here's a more detailed description:

Key Features and Applications:

-

Aluminum is favored for its lightweight nature, allowing for fuel efficiency and ease of handling, as well as its ability to be cast or machined to precise specifications.

-

Aluminum molds are commonly manufactured using casting and CNC machining processes.

-

Aluminum molds can be designed to accommodate complex shapes and surface details, allowing for customization of the roof's design and aesthetics.

-

Aluminum molds offer good strength and durability, making them suitable for both prototype and high-volume production.

-

Beyond car roofs, these molds can be used for other rotational molding applications, like tractor canopies, and for producing various plastic components.

-

Aluminum molds can offer a good balance between quality and cost, especially when compared to other molding processes like injection molding.

-

Different surface finishes, such as sandblasting (for a textured look) or smooth finishes, can be applied to the mold cavity based on the desired product finish.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email