- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

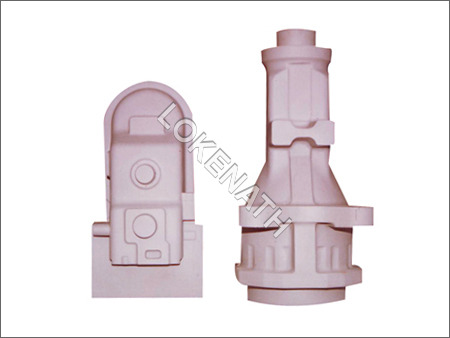

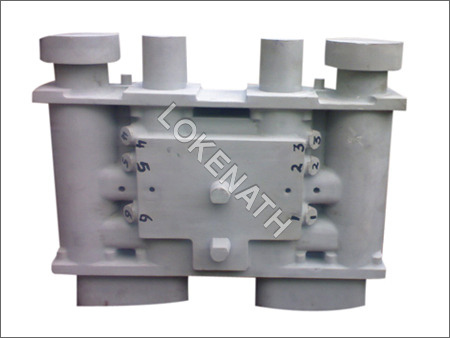

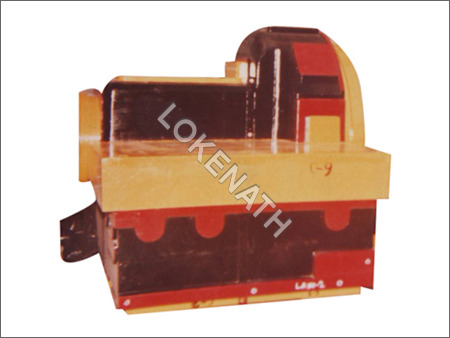

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

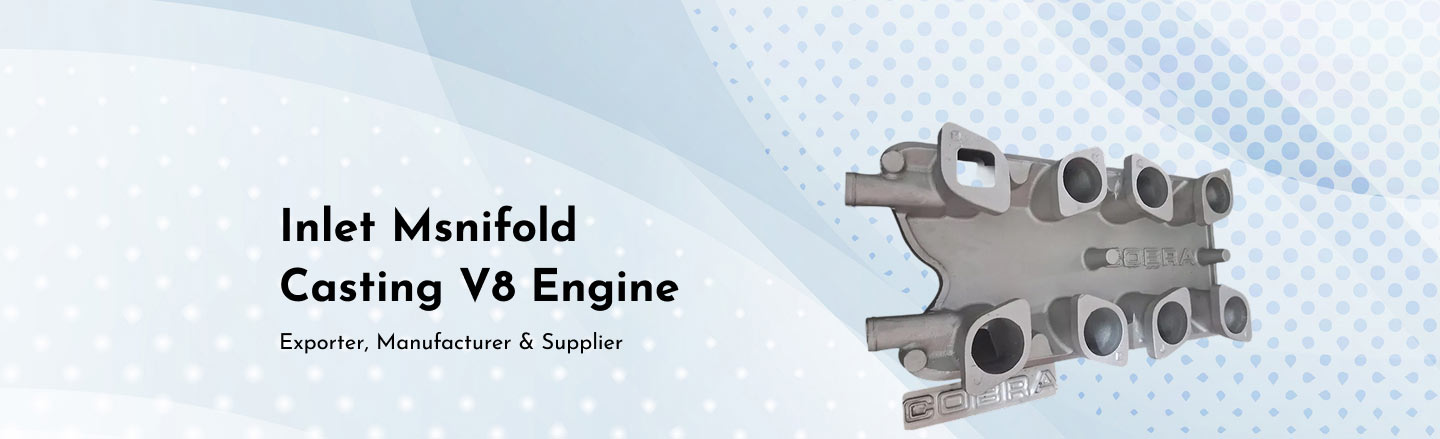

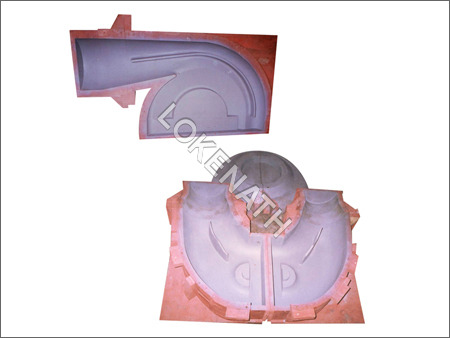

Industrial Wooden Pattern Castings

Product Details:

- Product Type Industrial Wooden Pattern Casting

- Casting Process Sand Casting

- Application Industrial Casting Moulds

- Method Hand Crafted

- Surface Treatment Polished

- Color Brown

- Click to view more

X

Industrial Wooden Pattern Castings Price And Quantity

- 1 Unit

- INR

Industrial Wooden Pattern Castings Product Specifications

- Hand Crafted

- Industrial Casting Moulds

- Industrial Wooden Pattern Casting

- Polished

- Brown

- Sand Casting

Industrial Wooden Pattern Castings Trade Information

- as per requirements Per Day

- As per requirement Days

- Yes

- All India

Product Description

We are one of the fastest growing manufacturers, exporters and suppliers of Industrial Wooden Pattern in the international as well as domestic market. Made of high grade wood, these patterns are widely used in various diverse industrial sectors such as automobile, heavy engineering and heavy vehicles for packaging of various products. Moreover, the range of finest quality Industrial Wooden Pattern offered by us holds no substitute in terms of performance in their respective applications.

Features

- Durable

- Superior design

- Superior finish standard

Precision Engineering for Exceptional Casting

Our wooden patterns are manufactured using high-grade hardwood and crafted by skilled artisans, ensuring accurate dimensions and a polished finish. Each piece guarantees excellent repeatability, maintaining a consistent 1 mm tolerance to deliver high-quality industrial castings.

Custom and Standard Shapes to Suit Your Needs

We provide patterns in both custom and standard designs, accommodating a diverse range of industrial applications. Whether you require unique solutions or established designs, our flexibility guarantees the right fit for your molding processes.

Reliable Performance and Long Lifespan

Designed to withstand demanding foundry conditions, our patterns can resist heat up to 120C and support up to 1000 castings. This longevity reduces replacement frequency, making them a cost-effective choice for industrial operations.

FAQs of Industrial Wooden Pattern Castings:

Q: How are the industrial wooden patterns created for sand casting?

A: Each pattern is handcrafted from high-quality hardwood by skilled artisans. The process involves shaping, finishing, and polishing the wood to achieve precise dimensions, smooth surfaces, and the required pattern type whether single piece, split, or match plate making them ideal for sand casting applications.Q: What advantages do these wooden pattern castings offer compared to other materials?

A: Wooden patterns are lightweight, easy to handle, and offer excellent machinability for custom and complex shapes. Their smooth, polished finish ensures accurate molds, and their heat resistance up to 120C makes them suitable for repeated use in the foundry industry.Q: When should I use split or match plate patterns instead of a single piece?

A: Split or match plate patterns are recommended when producing complex parts where undercuts or intricate cavities are present. Single piece patterns are typically used for simpler shapes with direct release from the sand mold.Q: Where are these wooden patterns primarily used?

A: These patterns are widely used in industrial foundries for creating molds in the sand casting process. They are also suitable for applications requiring prototyping or small-to-medium batch production of metal castings.Q: What is the typical lifespan of a wooden pattern in industrial casting applications?

A: With proper care and moderate operating conditions, each wooden pattern supports up to 1000 castings, thanks to the robust hardwood material and precise finishing process.Q: How does the surface finish of these patterns affect the final casting?

A: The smooth and accurate finish of the pattern directly contributes to the quality of the casting, minimizing the need for additional machining and ensuring a higher-quality surface on the final metal part.Q: What benefits can exporters, manufacturers, and suppliers in India expect from using these patterns?

A: By utilizing these patterns, exporters and manufacturers benefit from enhanced product consistency, reduced lead times for new designs, and cost savings from the long lifespan and reliability of each pattern.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email