- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

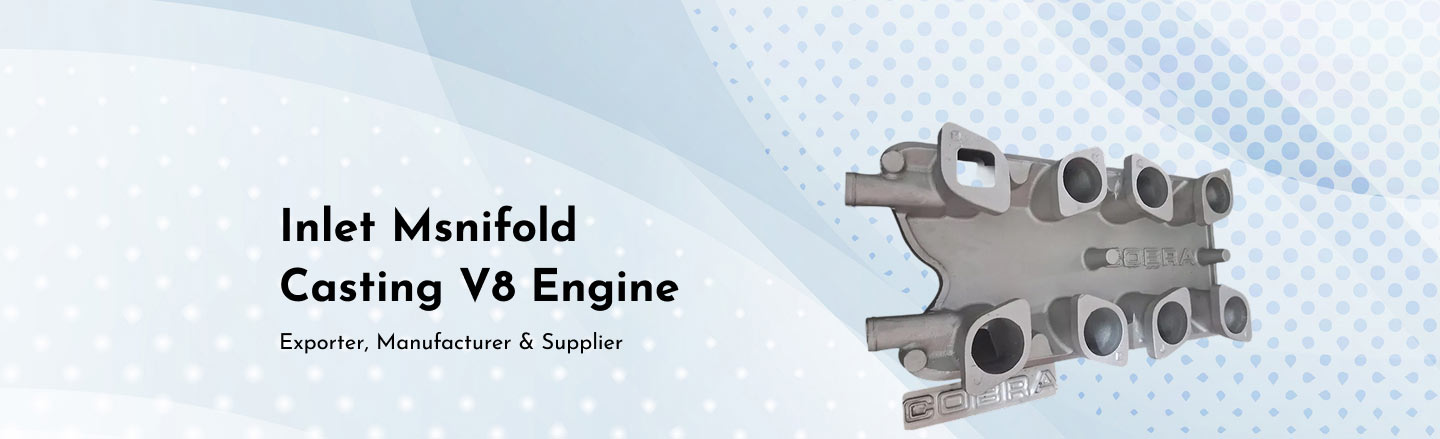

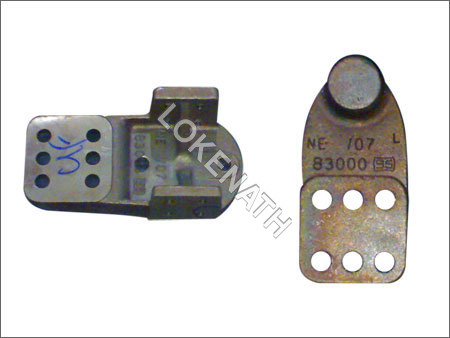

Defence Aluminium Sand Casting

Product Details:

- Product Type Aluminium Casting

- Casting Process Sand Casting

- Application Defence Industries

- Method Sand Casting

- Surface Treatment Coated

- Color Silver

- Click to view more

X

Defence Aluminium Sand Casting Price And Quantity

- 1 Unit

- INR

Defence Aluminium Sand Casting Product Specifications

- Sand Casting

- Sand Casting

- Defence Industries

- Aluminium Casting

- Silver

- Coated

Defence Aluminium Sand Casting Trade Information

- as per requirements Per Day

- As per requirement Days

- Yes

- All India

Product Description

With 15 years of experience, we are engrossed in manufacturing, exporting and supplying superior quality Defence Aluminium Sand Casting. Manufactured with perfection using supreme grade aluminium, the offered casting is easily available in the market to our valued patrons at cost effective rates. Widely used in automotive, mechanical and electrical industries, this is mostly preferred by clients for sand casting purpose. Moreover, we offer the provided Defence Aluminium Sand Casting to our esteemed patrons at rock bottom rates.

Features:

- Robust design

- Light weight

- Can withstand high temperature

- Fine finish

Precision and Customization for Defence Applications

Our sand casting process allows for intricate, fully customized shapes tailored to the unique requirements of defence equipment. With a strict tolerance of 0.05 mm and the use of high-quality aluminium, each casting delivers outstanding dimensional accuracy and reliability. Combined with comprehensive heat treatment and CNC machining, we ensure every part meets the highest industry standards.

Durable and Corrosion-Resistant Finish

Utilizing advanced heat treatment, coating, and CNC machining, our castings attain a surface hardness of up to 80 HRB and excellent resistance to corrosion. This results in components that withstand harsh operating environments, reduce maintenance needs, and extend operational service lifemaking them ideal for defence scenarios.

Reliable Supply and International Standards Compliance

We are a leading exporter, manufacturer, and supplier in India, capable of producing up to 500 pieces monthly. All our products conform to both IS and ASTM international standards, ensuring consistent quality for our defence-grade aluminium sand castings. Our efficient processes and quality management guarantee timely delivery to global clients.

FAQs of Defence Aluminium Sand Casting:

Q: How are Defence Aluminium Sand Castings manufactured to achieve such precise tolerances?

A: We use advanced sand casting techniques, followed by heat treatment and CNC machining, to ensure each component meets the strict tolerance of 0.05 mm. This multi-stage approach guarantees exceptional accuracy and product integrity.Q: What makes these aluminium castings suitable for defence industry applications?

A: Our castings offer superior machinability, up to 80 HRB surface hardness, excellent corrosion resistance, and customizability in shape. These attributes ensure reliable performance and longevity in demanding defence environments.Q: When is aluminium sand casting preferred over other manufacturing methods in defence applications?

A: Aluminium sand casting is chosen when complex, customized shapes and tight tolerances are needed in medium production volumes. Its ability to deliver robust, lightweight, and corrosion-resistant parts is crucial for defence projects.Q: Where can these defence aluminium sand castings be used?

A: They are widely utilized in various defence equipment and machinery, including vehicle components, housings, mounts, and brackets, where high precision, strength, and corrosion resistance are essential.Q: What is the process for ensuring corrosion resistance and durability of these castings?

A: After sand casting, the aluminium parts undergo heat treatment, CNC machining for precise finishing, and a specialized surface coating that greatly enhances their resistance to environmental and chemical corrosion.Q: What are the benefits of sourcing aluminium sand castings from you as an exporter and manufacturer in India?

A: Clients benefit from our adherence to global IS and ASTM standards, consistent product quality, customizable solutions, reliable monthly production capacity, and timely international delivery, all supported by extensive expertise in defence manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email