- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

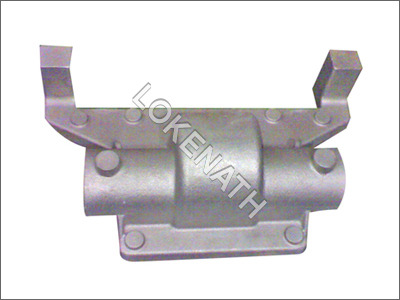

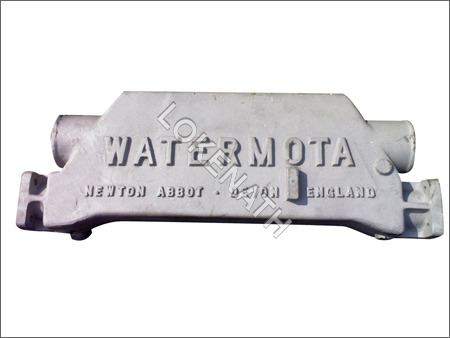

Heat Exchanger Aluminium Sand Casting

Product Details:

- Product Type Heat Exchanger Casting

- Casting Process Aluminium Sand Casting

- Application Heat Exchanger, Air Conditioning, Industrial Equipment

- Method Sand Casting

- Surface Treatment Smooth Sand Blasted

- Weight (kg) 12

- Color Silver Grey

- Click to view more

X

Heat Exchanger Aluminium Sand Casting Price And Quantity

- 1 Unit

- INR

Heat Exchanger Aluminium Sand Casting Product Specifications

- Heat Exchanger, Air Conditioning, Industrial Equipment

- Aluminium Sand Casting

- Heat Exchanger Casting

- 12

- Silver Grey

- Sand Casting

- Smooth Sand Blasted

Heat Exchanger Aluminium Sand Casting Trade Information

- Per Day

- Days

- Yes

- All India

Product Description

Considering the increasing market demands, we are affianced in manufacturing, exporting and supplying a large variety of Heat Exchanger Aluminium Sand Casting. As per set industry norms, the offered casting is manufactured using top notch quality aluminium with the help of cutting edge techniques. Having sturdy design and fine finish, the provided casting is highly demanded in metal industry. Apart form this, our esteemed patrons can easily buy the offered Heat Exchanger Aluminium Sand Casting from us at rock bottom rates.

Features:

- Accurate shape

- Long life

- Safe to use

- Smooth edges

Precision-Crafted Aluminium Castings

Our aluminium sand castings are engineered to exact specifications, with fine tolerances and customizable features to fit unique requirements. Using premium LM6 or ADC12 alloys, we ensure durability and optimal performance for every heat exchanger application.

Versatile Applications and Customization

Designed for use in heat exchangers, air conditioning systems, and a wide array of industrial equipment, these castings are available in various shapes and sizes. Our sand casting process allows for modifications as per your specific design, ensuring seamless integration into your projects.

Reliable Durability and Finish

Each casting is finished with a smooth sand-blasted surface that resists corrosion and provides a sleek silver-grey appearance. The robust aluminium alloys and attentive finishing work deliver reliable strength, even in high-temperature environments up to 250C.

FAQs of Heat Exchanger Aluminium Sand Casting:

Q: How is the aluminium sand casting process carried out for heat exchanger parts?

A: The aluminium sand casting process involves pouring molten aluminium alloy, such as LM6 or ADC12, into custom sand molds based on your design drawings. After cooling and solidification, the casting is removed, finished with options like as-cast or machining, and typically receives a smooth sand-blasted surface treatment for enhanced appearance and corrosion resistance.Q: What are the benefits of using LM6 or ADC12 aluminium alloys in these castings?

A: LM6 and ADC12 alloys offer excellent corrosion resistance, high thermal conductivity, and sufficient strength for demanding environments. These properties make them ideal for heat exchangers, ensuring long life, optimal performance, and the ability to withstand temperatures up to 250C.Q: Can I customize the shape, thickness, or size of the heat exchanger casting?

A: Yes, our sand casting process is highly flexible and allows you to customize the shape, thickness (average 5 mm), weight, and dimensions according to your specific drawings and requirements. Our team will work closely with you to ensure your product fits your application precisely.Q: Where are these aluminium sand castings typically used?

A: These castings are most commonly used in heat exchangers, air conditioning units, and various types of industrial equipment. Their customizable design and robust properties support efficient thermal management in diverse operational environments.Q: What is the minimum order quantity and typical production lead-time?

A: The minimum order quantity (MOQ) for our aluminium heat exchanger sand castings is 10 pieces. Production lead-time can vary depending on the complexity and customization required but is typically communicated during the consultation and quotation process.Q: How does the finishing process improve the quality of the casting?

A: After casting, surfaces can be left as-cast or further machined for added precision. All parts undergo smooth sand blasting to remove any residues and create a uniform, corrosion-resistant finish, resulting in improved durability and aesthetics.Q: Why should I choose aluminium sand casting for my heat exchanger components?

A: Aluminium sand casting enables efficient production of complex, custom-shaped parts with fine tolerances at competitive costs. It is especially suited for medium to large batch requirements, offering robust mechanical properties, good heat transfer capabilities, and resistance to corrosion, making it ideal for heat exchangers and similar applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email