- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

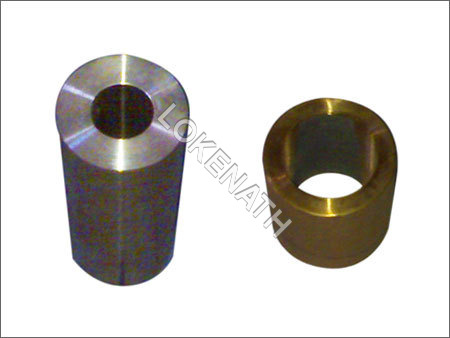

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

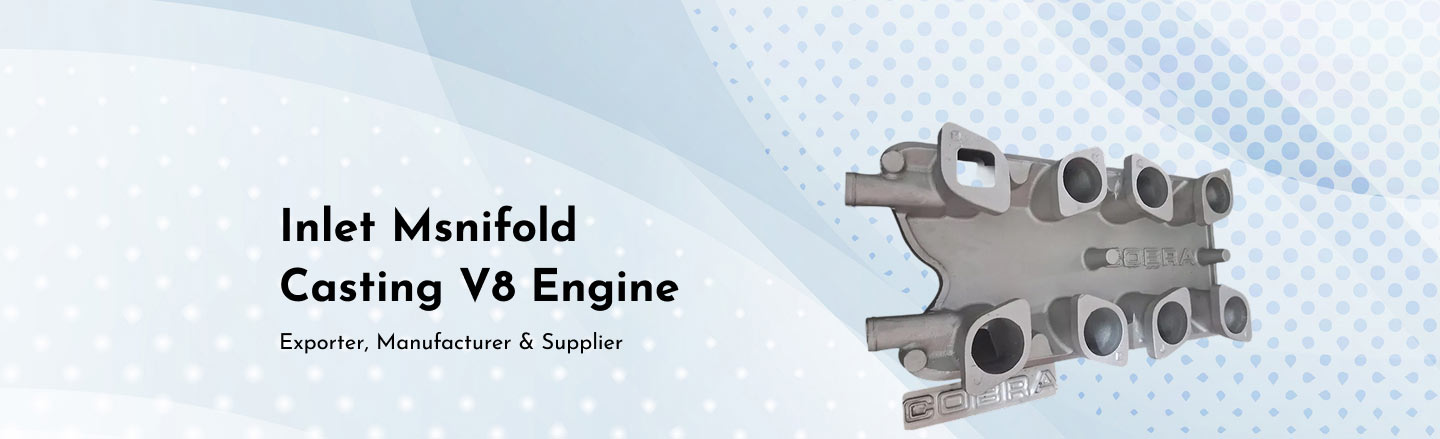

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

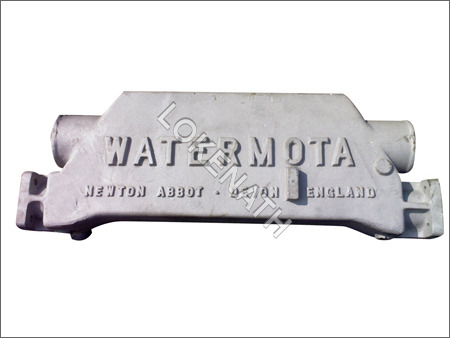

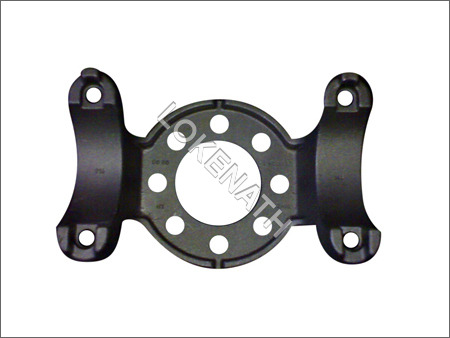

Power Transmission Aluminium Sand Casting

550 INR/Piece

Product Details:

- Product Type Aluminium Casting

- Casting Process Manual Molding

- Application Power Transmission Equipment

- Method Sand Casting

- Surface Treatment Sand Blasted

- Weight (kg) 3.5

- Color Silver Grey

- Click to view more

X

Power Transmission Aluminium Sand Casting Price And Quantity

- 550 INR/Piece

- 1 Unit

Power Transmission Aluminium Sand Casting Product Specifications

- Power Transmission Equipment

- Manual Molding

- Sand Blasted

- Sand Casting

- 3.5

- Silver Grey

- Aluminium Casting

Power Transmission Aluminium Sand Casting Trade Information

- Per Day

- Days

- Yes

- All India

Product Description

Power transmission aluminum sand casting is the process of creating large, complex, and cost-effective aluminum components for the power transmission industry using the sand casting method. This technique involves pouring molten aluminum into a mold made of compacted sand, which is created from a reusable pattern. The molten metal fills the mold's cavity, solidifies, and is then extracted after the sand mold is broken away, resulting in durable, lightweight, and corrosion-resistant parts like gearbox housings, transmission components, and industrial machinery parts.

The Sand Casting Process for Power Transmission Components

-

A reusable pattern, a precise replica of the final part, is made from wood, metal, or other durable materials.

-

The pattern is placed in a flask, and the mold is created by compacting a specialized sand mixture around it. This sand is typically reinforced with binders like clay or resin.

-

A sprue, runners, and risers are incorporated into the mold design to guide the molten aluminum into the cavity and manage metal flow, preventing defects.

-

Aluminum alloys are melted in a furnace to their liquid state and then poured into the sand mold's cavity.

-

The molten aluminum cools and solidifies within the mold.

-

Once solid, the sand mold is broken apart, and the aluminum casting is removed. The casting is then cleaned, rough edges are removed, and it may undergo further machining or finishing to meet specifications.

Key Characteristics for Power Transmission

-

Sand casting is an economical process, especially for large components and both low- and high-volume production runs.

-

Aluminum's inherent low density makes it ideal for power transmission components, contributing to fuel efficiency and easier handling.

-

Aluminum offers excellent resistance to corrosion, which is crucial for components exposed to various environmental conditions.

-

Sand-cast aluminum components possess good strength, toughness, and wear resistance, ensuring reliable performance.

-

The process accommodates complex shapes, internal features, and a wide range of part sizes, making it suitable for intricate designs.

Common Applications in Power Transmission Gearbox housings, Transmission components, Automotive parts, Industrial machinery components, and Material handling equipment parts.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email