- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

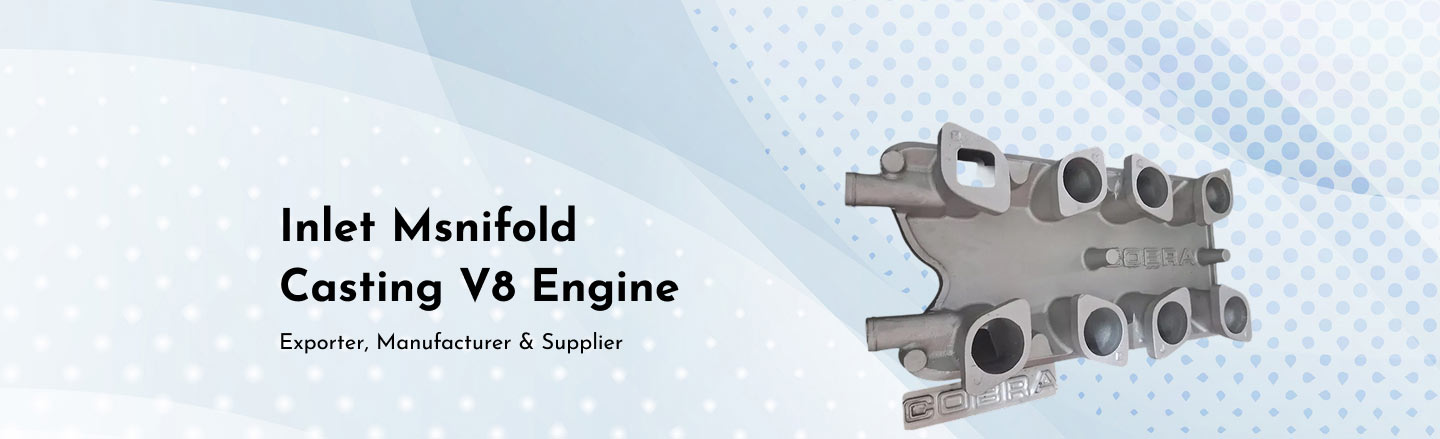

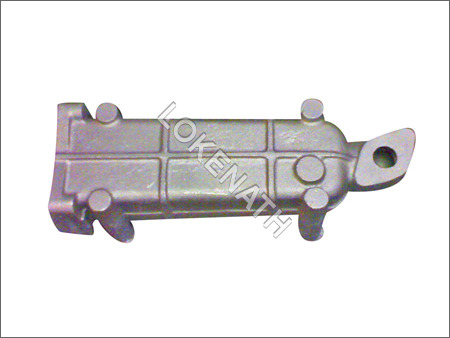

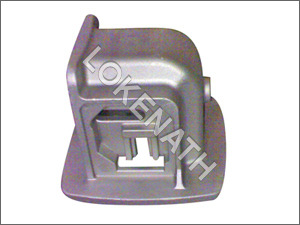

Gravity Die

Product Details:

- Material Aluminum Alloy

- Application Metal Casting Industries, Automotive, Engineering Components

- Processing Gravity Die Casting

- Surface Smooth, Polished

- Machining Type Precision Machining

- Click to view more

X

Gravity Die Price And Quantity

- 1 Unit

Gravity Die Product Specifications

- Aluminum Alloy

- Metal Casting Industries, Automotive, Engineering Components

- Precision Machining

- Smooth, Polished

- Gravity Die Casting

Gravity Die Trade Information

- 50 Unit Per Day

- 2 Days

- Yes

- As per requirement

- All India

Product Description

Since our inception in the year 2001, we have been counted among prominent entities by offering top grade Gravity Die Casting. The provided casting is manufactured under the strict observation of deft professionals using top notch quality raw materials and innovative techniques. This is used in various industrial applications for providing leak proof casting. Moreover, we offer the provided Gravity Die Casting to our valued patrons at rock bottom rates.

Features:

- Optimum strength

- Robust design

- High aesthetic value

- Well finished and polished

Advanced Casting Solution for Precision Industries

Gravity Dies are ideally suited for high-precision requirements in the metal casting, automotive, and engineering sectors. Each rectangular die is manufactured using aluminum alloy and advanced permanent mold casting techniques, ensuring durability and exceptional performance. Whether used for intricate components or standard manufacturing needs, these dies deliver smooth and polished finishes, making them a reliable choice for quality-focused industries.

Superior Corrosion Resistance and Customizable Options

Engineered to withstand harsh environments, our Gravity Dies feature high corrosion resistance and robust build quality. Customization is available upon request, enabling clients to tailor the dies specifications for specialized projects. This adaptability, combined with the products silver grey finish and polished surface, assures both aesthetic appeal and prolonged service life.

FAQs of Gravity Die:

Q: How is the gravity die manufactured and what materials are used?

A: Our gravity dies are produced using the permanent mold casting technique, utilizing high-quality aluminum alloy. This process allows for smooth, polished surfaces and ensures the die maintains tight tolerances and high corrosion resistance.Q: What applications are these rectangular gravity dies suitable for?

A: These gravity dies are ideal for metal casting industries, automotive components, and engineering parts where precision and durability are crucial. Their robust design and versatility make them suitable for a range of industrial environments.Q: When is it beneficial to use a gravity die with high tolerance and corrosion resistance?

A: Utilizing a gravity die with 0.01 mm tolerance and high corrosion resistance is especially beneficial in situations where dimensional accuracy and long-term exposure to challenging environments are critical, such as in automotive and heavy engineering sectors.Q: Where are your gravity dies exported and supplied from?

A: Our gravity dies are manufactured and exported from our facilities in India, serving clients worldwide. We are a trusted supplier and manufacturer for various industries requiring precision casting solutions.Q: What is the process and advantage of precision machining in your dies?

A: Every gravity die undergoes advanced precision machining, which enhances dimensional accuracy, uniformity, and performance. This results in reliable, repeatable castings with minimal post-casting processing required.Q: How can customers request customization for specific applications?

A: Customers can request customization by providing their particular design or technical requirements. Our engineering team will collaborate closely to manufacture dies that meet the exact needs of the project.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email