- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

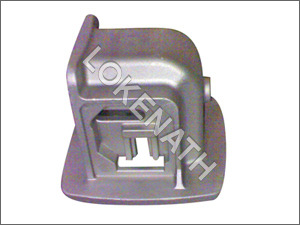

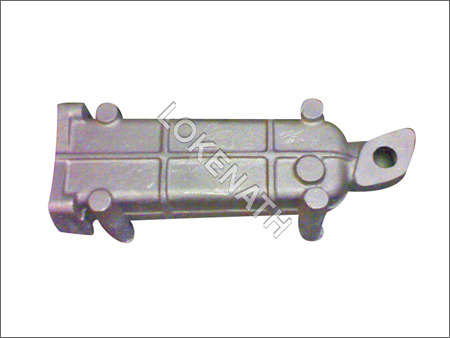

Leak Proof Aluminium Gravity Die Castings

350 INR/Bale

Product Details:

- Material Aluminium

- Application Industrial machinery, Automotive parts, Hydraulic equipment, Electrical enclosures

- Processing Gravity Die Casting

- Surface Smooth, Leak Proof, Corrosion Resistant

- Machining Type CNC Machining, Drilling, Milling, Tapping

- Click to view more

X

Leak Proof Aluminium Gravity Die Castings Price And Quantity

- 1 Unit

- 350 INR/Bale

Leak Proof Aluminium Gravity Die Castings Product Specifications

- Industrial machinery, Automotive parts, Hydraulic equipment, Electrical enclosures

- Smooth, Leak Proof, Corrosion Resistant

- Aluminium

- CNC Machining, Drilling, Milling, Tapping

- Gravity Die Casting

Leak Proof Aluminium Gravity Die Castings Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 100 Unit Per Day

- 1 Days

- Yes

- Asia

- All India

Product Description

Considered as a quality oriented manufacturer, exporter and supplier, we provide the finest grade Leak Proof Aluminium Gravity Die Castings. By our diligent professionals, these castings are manufactured using premium quality aluminium and cutting edge techniques. The offered castings are extensively used for providing vacuum cavity proof shape. Along with this, the provided Leak Proof Aluminium Gravity Die Castings are operated at very high voltage, purchased at rock bottom rates.

Features:

- Robust design

- Well finished and polished

- Excellent tolerance

- Sturdy construction

Leak-proof aluminum gravity die castings are durable, dimensionally accurate components made by pouring molten aluminum into a reusable mold under the force of gravity. These castings are known for their strength, long service life, and ability to withstand high pressures, making them suitable for various industrial applications, particularly in the power electronics and high-voltage sectors.

Here's a more detailed look:

Process:

-

This process involves pouring molten aluminum into a mold (die) made of metal, using gravity to fill the cavity.

-

Unlike sand casting, gravity die casting uses a permanent mold, which allows for more precise dimensions and a higher production rate.

-

While the process can be manual for some steps, it can also be automated, especially for large-scale production.

Characteristics:

-

The castings are designed to prevent leakage of fluids or gases, ensuring the integrity of the component in various applications.

-

Aluminum alloys used in these castings provide good mechanical properties and resistance to wear and tear, ensuring a long service life.

-

Gravity die casting allows for tight tolerances and precise dimensions, which is crucial for complex parts and assemblies.

-

Aluminum alloys are naturally resistant to corrosion, making these castings suitable for harsh environments.

-

These castings can be engineered to meet specific mechanical requirements, including tensile strength, yield strength, and elongation.

Applications:

- Power Electronics: Used in high-voltage applications and power electronics due to their leak-proof and durable nature.

- Automotive: Found in various automotive parts, including engine components, brake calipers, and other parts requiring high strength and precision.

- Industrial Applications: Used in a wide range of industrial equipment and machinery.

Benefits:

- High-Quality Components: Gravity die casting produces parts with superior surface finish and dimensional accuracy.

- Cost-Effective: Compared to some other casting methods, gravity die casting can be a cost-effective solution, especially for larger production volumes.

- Reduced Material Waste: The reusable mold minimizes material waste compared to sand casting.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email