- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

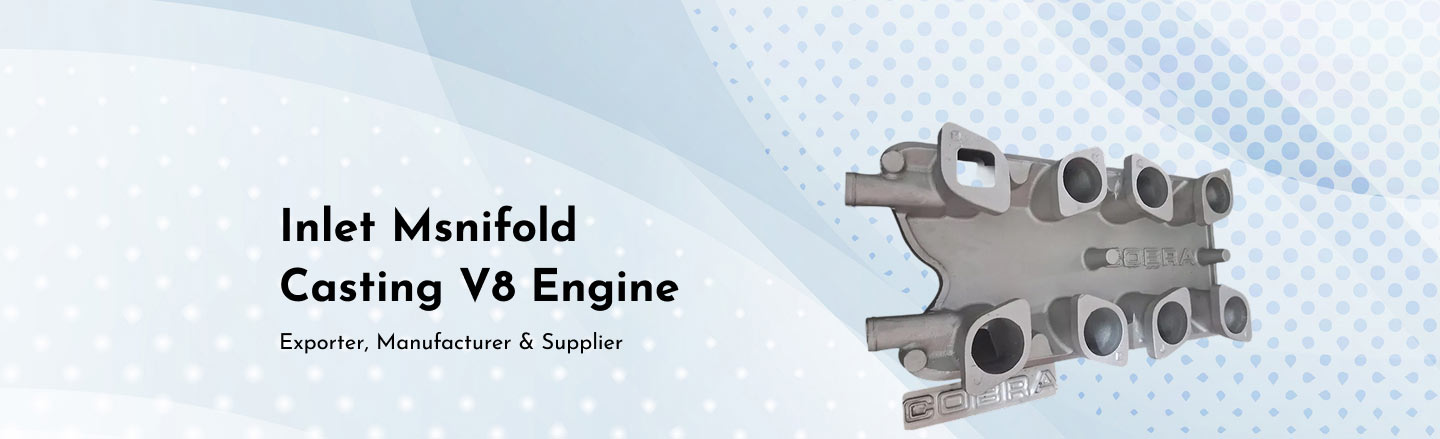

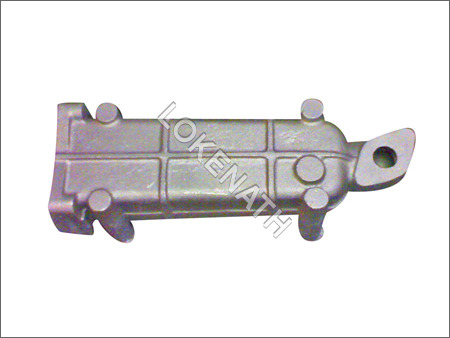

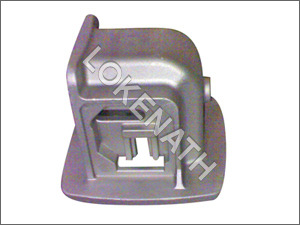

Gravity Die Casting

345 INR/Bale

Product Details:

- Material Aluminium Alloy

- Application Engineering and Automotive Industries

- Processing Gravity Die Casting

- Surface Anodized Finish

- Machining Type CNC Machining

- Click to view more

X

Gravity Die Casting Price And Quantity

- 345 INR/Bale

- 1 Unit

Gravity Die Casting Product Specifications

- CNC Machining

- Gravity Die Casting

- Aluminium Alloy

- Anodized Finish

- Engineering and Automotive Industries

Gravity Die Casting Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- Per Day

- Days

- Yes

- Asia

- All India

Product Description

Our organization holds a respectable stand in the market as a reliable and pioneering manufacturer, exporter and supplier of superior grade Aluminium Gravity Die Casting in the worldwide market. With the help of professional supervision we design &manufacture these castings using quality approved Aluminium in a qualitative manner. Offered in various sizes and specifications, our Aluminium Gravity Die Casting is a railway engine part that is subject to severe stresses during operation.

Features

- Dimensionally precise

- High tensile strength

- Durability

-

Unlike some other casting methods, gravity die casting relies solely on the force of gravity to fill the mold, minimizing turbulence and potential defects.

-

The process utilizes a permanent mold, often made of steel or cast iron, which can be used repeatedly, making it suitable for medium to high-volume production.

-

It's commonly used for non-ferrous metals like aluminum, zinc, magnesium, and copper-based alloys.

-

Gravity die casting offers good dimensional accuracy and surface finish, particularly when compared to sand casting.

-

It's widely used in industries like automotive, aerospace, and others requiring durable, high-precision components.

-

Good surface finish, close dimensional tolerances, and a potential for increased production rates with automation are some of the key benefits.

Gravity die casting is a metal casting process where molten metal is poured into a reusable mold (die) using only the force of gravity to fill the cavity. It's also known as permanent mold casting due to the durable, often steel or cast iron, mold used. This method is favored for producing high-quality, dimensionally accurate parts, especially with thicker walls, and offers a smooth surface finish.

Here's a more detailed look:

Key Features:

Process Steps (Simplified):

-

The reusable mold is preheated and coated with a lubricant or die coat to aid in metal flow and release.

-

Molten metal is poured into the mold cavity, typically through a runner system, using gravity as the driving force.

-

The molten metal cools and solidifies within the mold.

-

The solidified casting is removed from the mold, often after the mold has cooled slightly.

-

The casting may undergo further finishing operations like trimming, machining, or heat treatment, depending on the specific application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email