- Home Page

- Company Profile

-

Our Products

- Aluminium Castings Products

- Aluminum Sand Castings

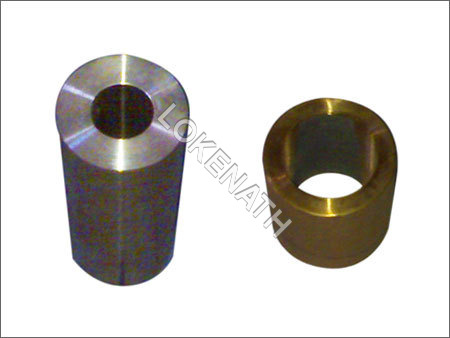

- Aluminium Bronze

- Leak Proof Casting

- Bronze Casting

- Aluminum Castings

- Aluminium Bronze Castings

- Aluminium send Castings

- Manganese Bronze

- Impeller Bronze Casting

- Power Distribution Casting

- Non Ferrous Castings

- Sand Casting

- Aluminium Sand Casting

- Intake Manifold Aluminum Sand Castings

- Defence Aluminium Sand Casting

- Tap Changer Aluminium Sand Casting

- Gear HSG Aluminium Sand Casting

- Aluminium Sand Casting

- Heat Exchanger Aluminium Sand Casting

- Aluminium Pump Sand Casting

- Power Transmission Aluminium Sand Casting

- Aluminum Gravity Die Castings

- Copper Based Alloys Castings

- Aluminum Moulds Castings

- Wooden Patterns Castings

- Metalic Patterns Castings

- Contact Us

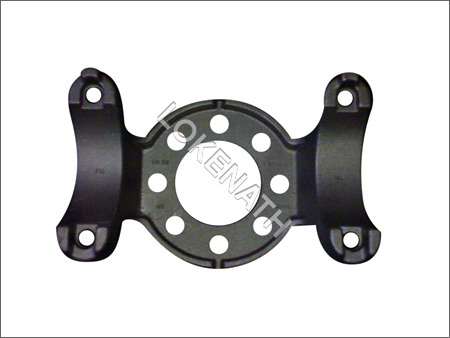

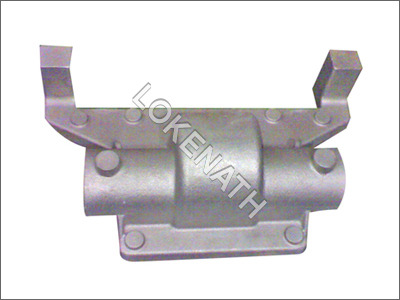

Sand Casting

350 INR/Piece

Product Details:

- Casting Process Sand Casting

- Surface Treatment Casting

- Click to view more

X

Sand Casting Price And Quantity

- 1 Unit

- 350 INR/Piece

Sand Casting Product Specifications

- Casting

- Sand Casting

Sand Casting Trade Information

- Cash in Advance (CID), Cheque

- Yes

- Asia

- All India

Product Description

Empowered by the state of art manufacturing facilities, our corporation has become known as the top most manufacturers, exporters and suppliers of VCB Aluminium Sand Casting. We are offering these castings in a variety of sizes & specifications and at cost effective prices, to meet the different needs and requirement of our valuable clients. Manufactured by using superior quality iron, this leak VCB Aluminium Sand Casting is find wide usage in locomotives.

Features

- Rugged structure

- Can sustain high voltage

- Corrosion resistance

-

A master pattern, slightly larger than the final part to account for shrinkage, is created.

-

Sand is packed tightly around the pattern in a two-part mold box (the cope and drag) to create a negative impression of the part.

-

The pattern is removed from the sand mold, leaving behind the desired cavity.

-

Molten metal is poured into the mold through a channel called a sprue, filling the cavity.

-

The metal cools and solidifies within the sand mold, taking on the shape of the cavity.

-

The sand mold is broken apart, and the finished casting is removed.

-

The rough casting undergoes further processes like machining to achieve final dimensions and remove any surface impurities.

-

Can be used to create a vast range of shapes, from small items to large parts like engine blocks.

How Sand Casting Works

Key Characteristics

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email